OBJECTIVE

During the final weeks of my 3-D design class, the instructor tasked us with creating a sock package for a user of our choice. The guidelines for the project were that we could only use E-flute corrugated cardboard - no adhesive and no graphics were permitted.

ROLE & DURATION

UX Design

Industrial Design

June '19 (3 weeks)

Defining My User Group

For this project, I decided to design for a shopper of the well known international art/clothing store - Totokaelo. The items found in the store can be described as simple and abstract, thus I set out to incorporate these characteristics in my design.

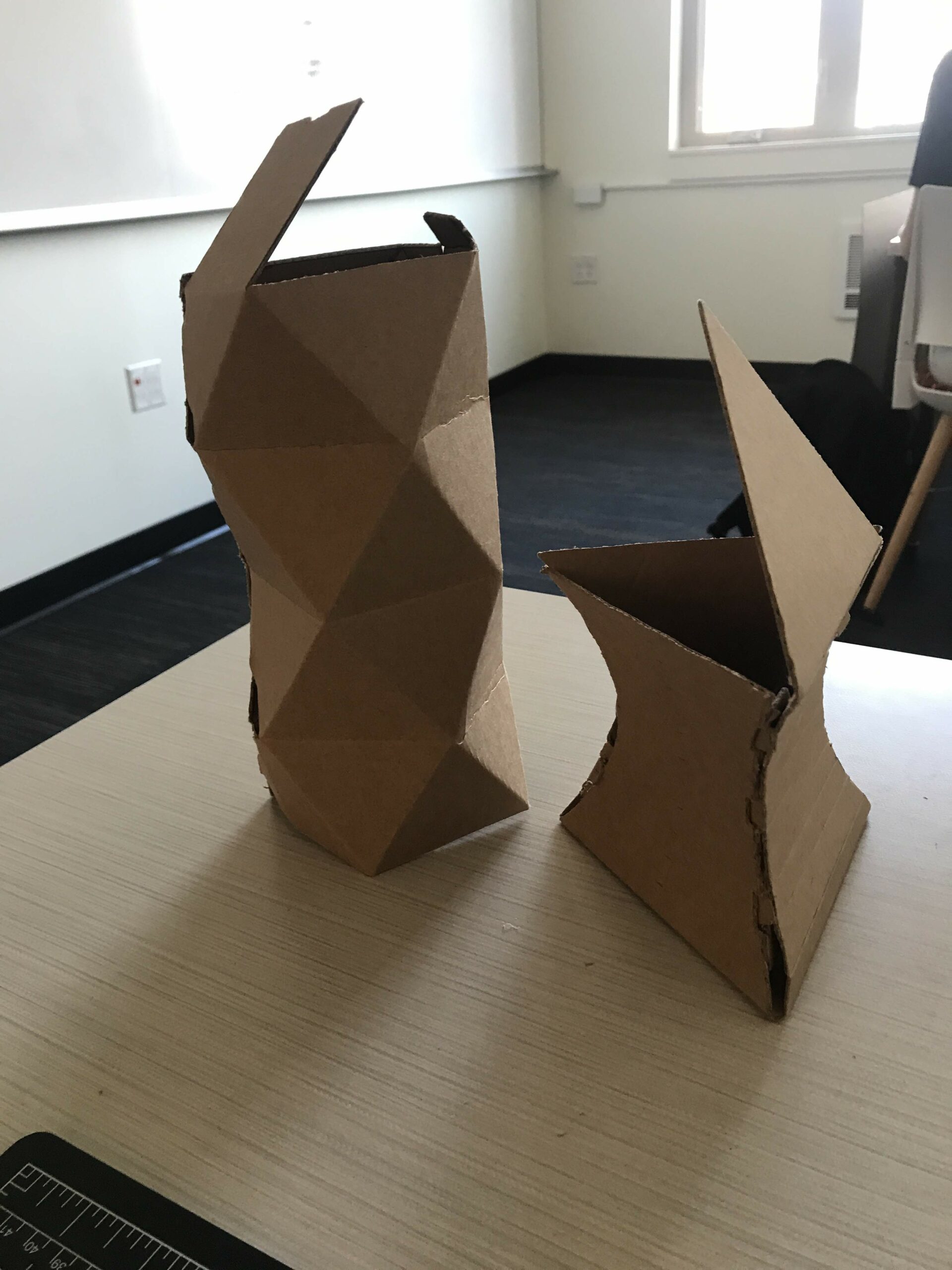

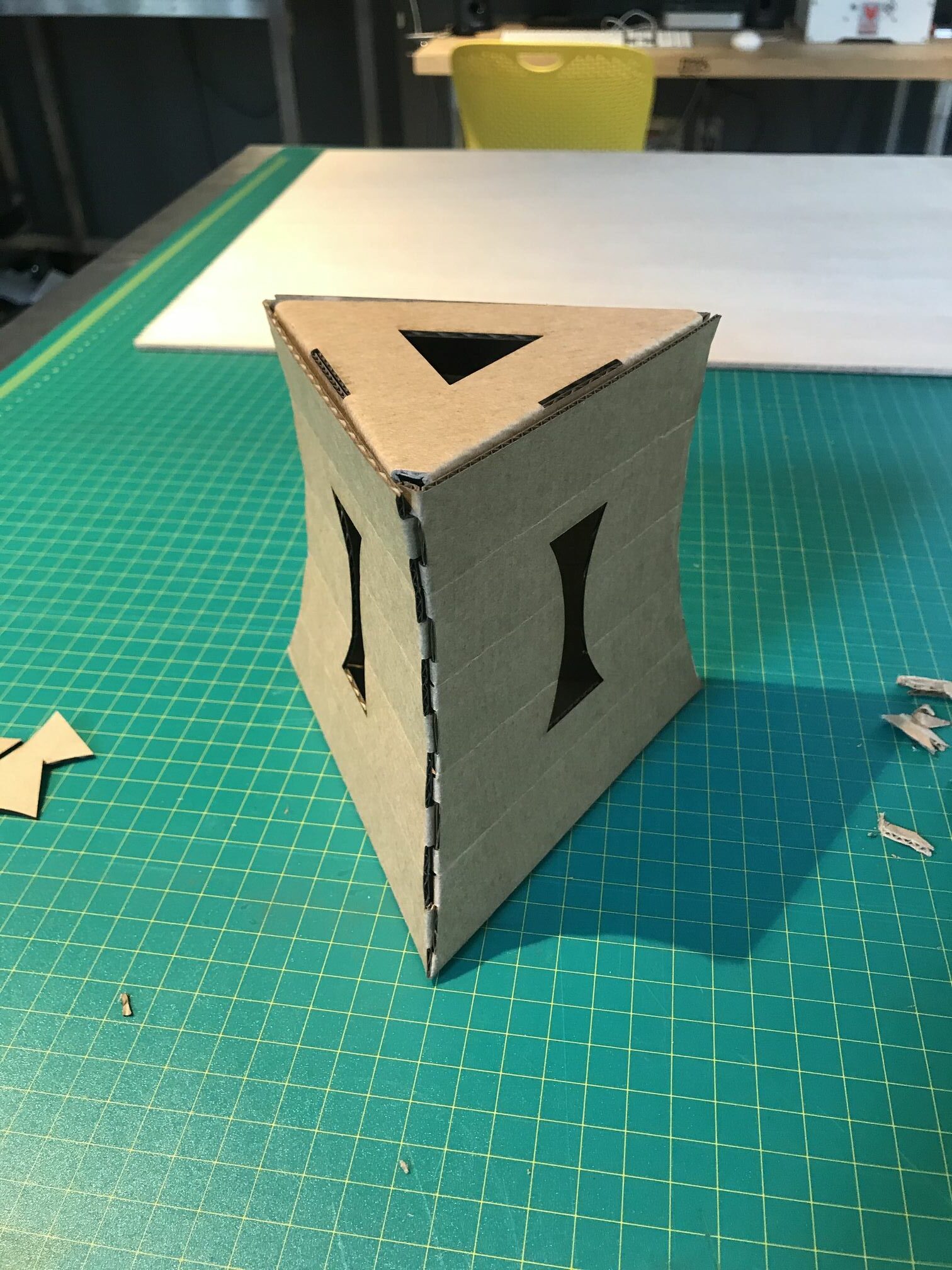

Preliminary Designs

With no prior experience working with E-flute cardboard, I began experimenting with different shapes and folds. My goal was to get used to the material and find a simple design that made sense for my user group.

KEY TAKEAWAYS

• Nets should be drawn prior to tracing on the E-flute.

• X-Acto knife cutting may not be my only option for cutting.

• Tabs and slots are a pain to manually measure and cut (via ruler and knife).

• I prefer organic design over geometric design for this project (the design on the right looks more intriguing).

A User-focused Design Solution

By brainstorming potential design solutions, I was able to isolate the key features of my design that I believed mattered most to my user. Features I strived to incorporate into my design included:

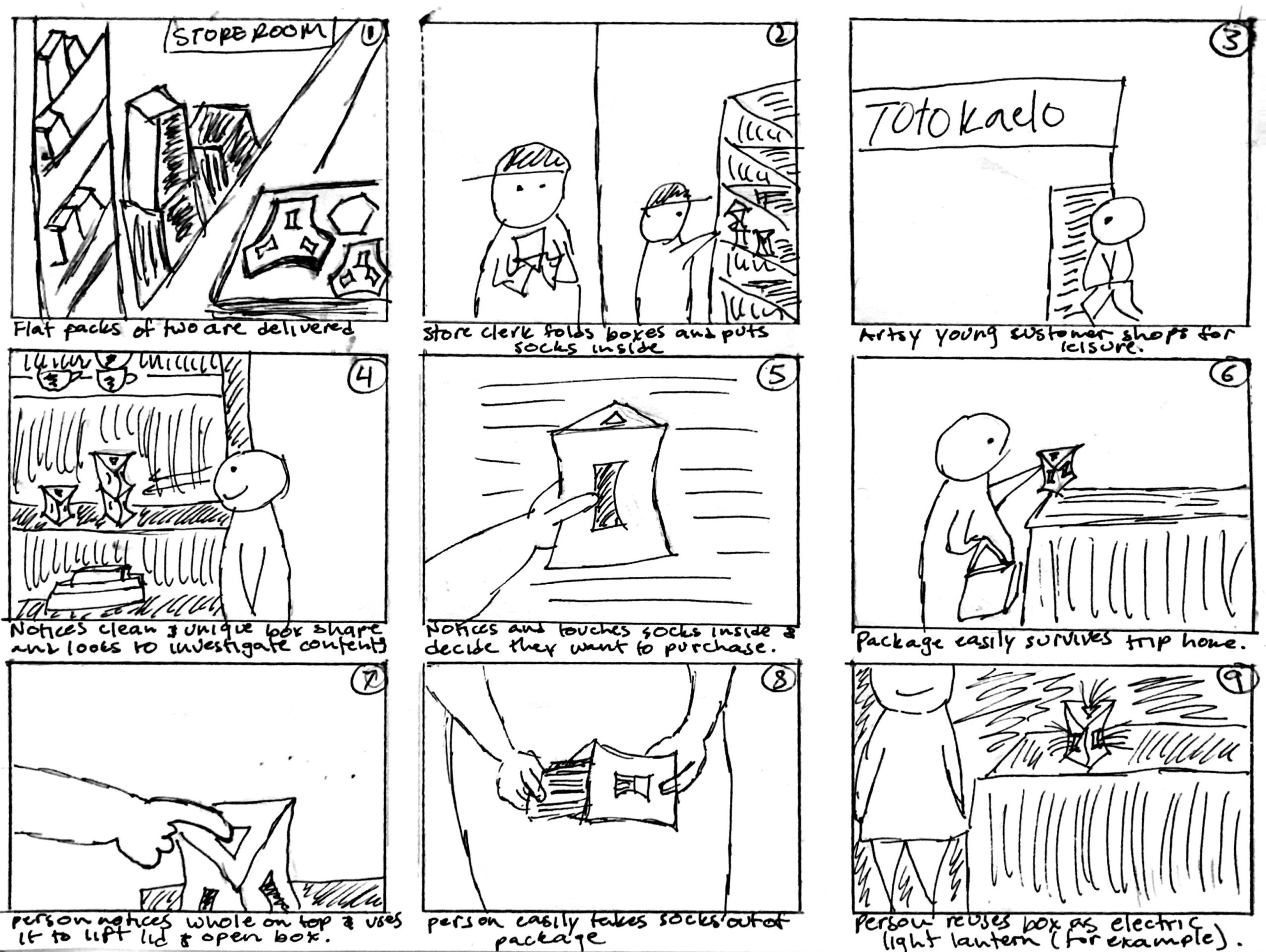

01

Flatpack delivery to the store for space-saving.

02

Each flatpack contains two packages for no material waste and cost-effectiveness.

03

Visual appeal on store shelves with easy access to sock material (so that the shopper knows what they are buying).

04

Reusability aspect (Totokaelo shoppers seem to be artsy and eco-friendly).

05

Easy to transport and open.

Storyboard

A visual representation to convey product usage and packaging experience based on the design requirements outlined above.

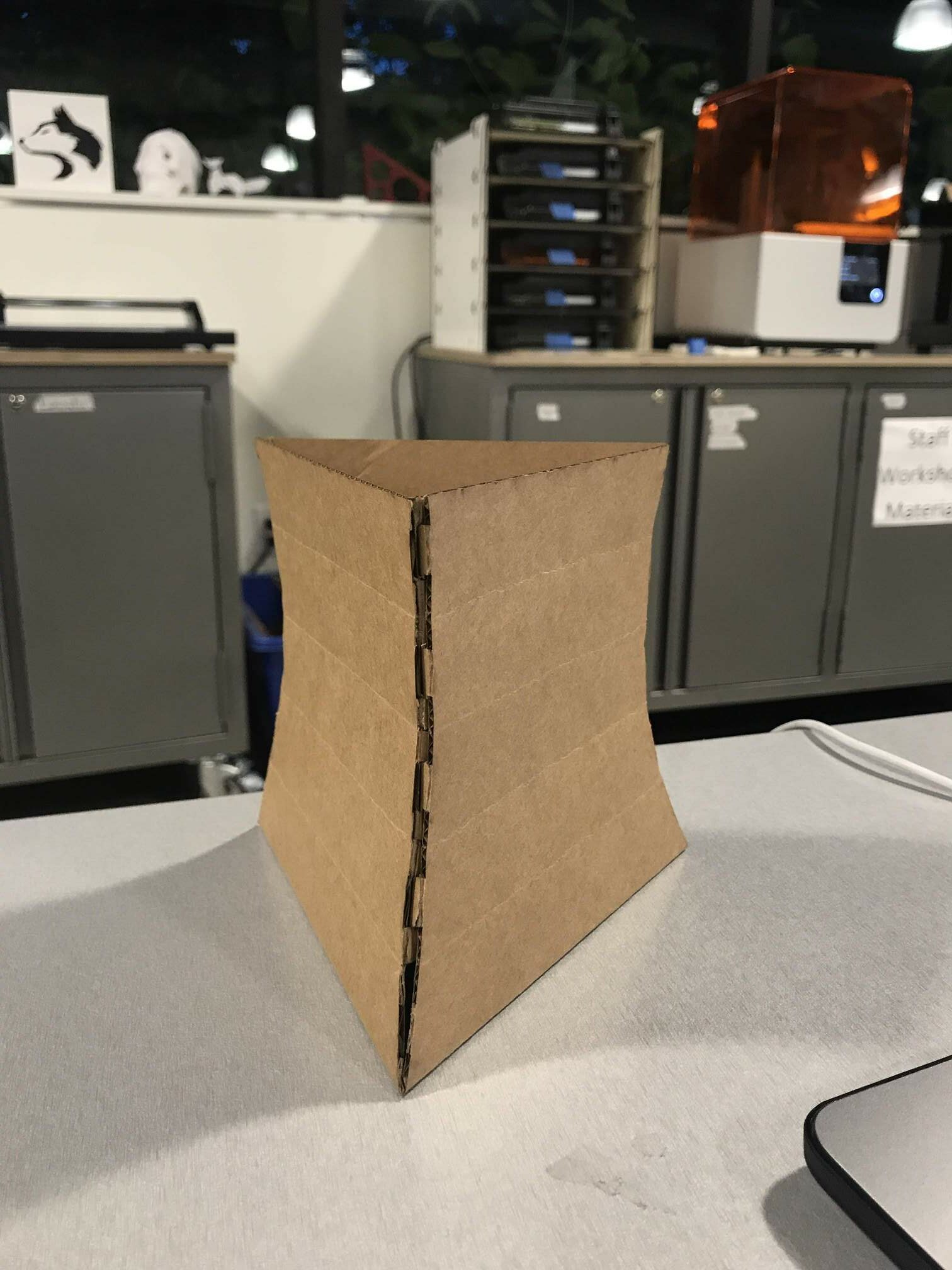

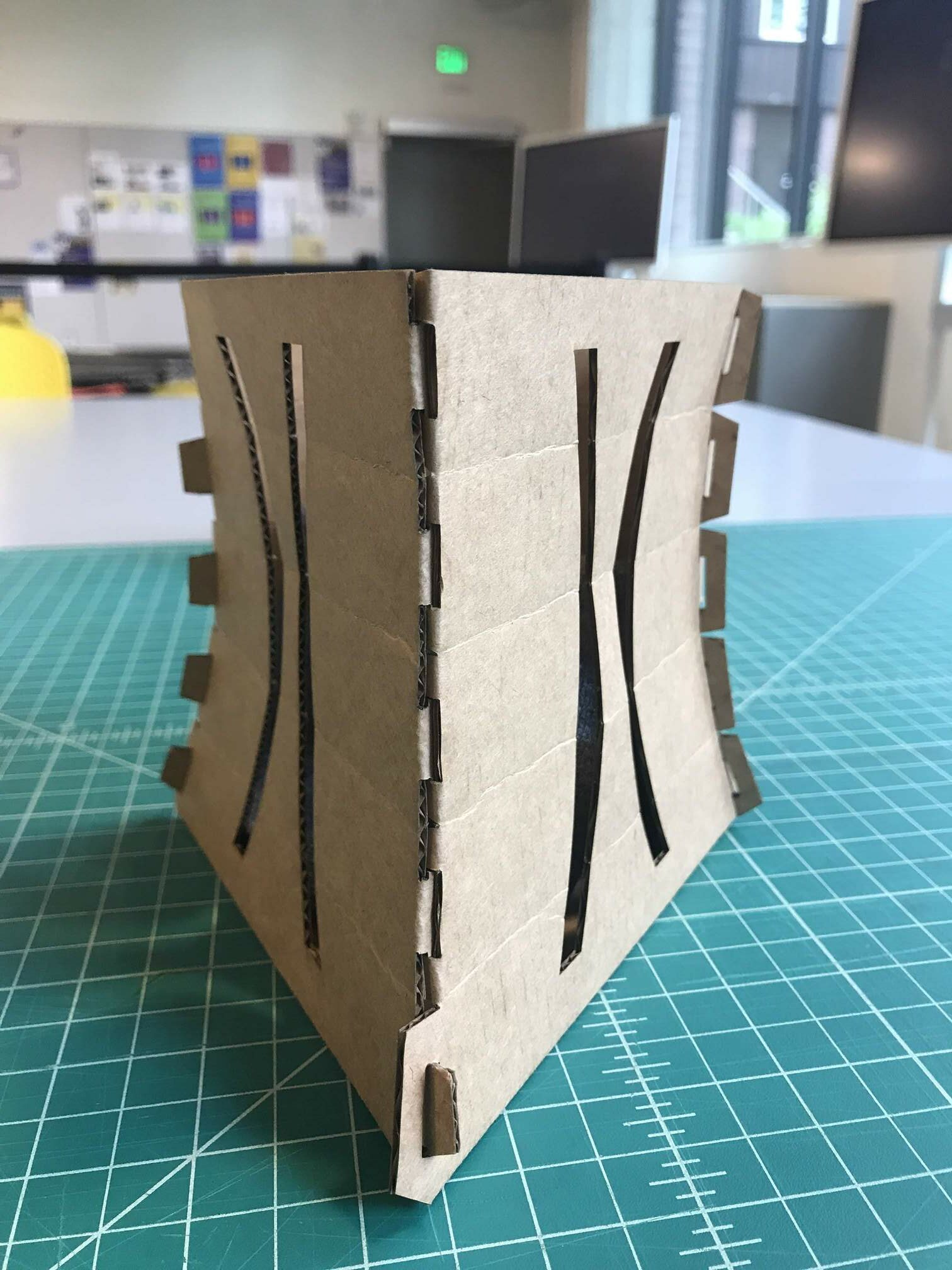

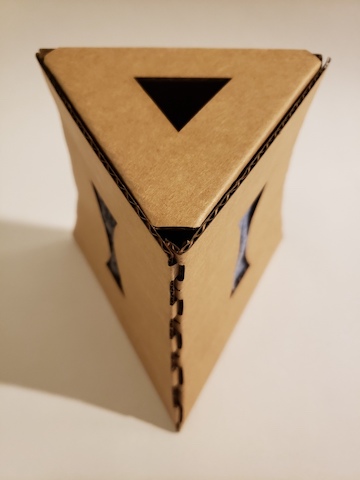

Making the Transition to Laser Cutting

I saw that I wasn’t getting as clean a result as I wanted when creating the packages by hand, so I started seeking alternative ways to cut out my cardboard nets.

Living right next to UW’s maker-space, the laser cutting machine seemed like a good choice. I transferred all of my hand-written nets onto Illustrator and ran my cardboard through the laser cutting machine.

The results were beyond satisfactory. My cut time went from 10 minutes to 1 minute; having my nets on Illustrator made it easier to make minor adjustments; the laser cutter allowed me to make very precise and small cuts for my tabs and slots.

Iterations Upon Iterations

Final Net & Product Shots

Selected Works

DIVVUPInteraction Design, Visual Design

CappuccinoVisual Design, Product Research

Patient AdvocacyService Design, UX Research

TecanUX Design, Information Architecture

AuroraUX Research, Service Design

Sock BoxIndustrial Design, Packaging Design

Interested?

I am always looking for new ways to get involved in my community and gain experience in industry - let's connect!